3Shape indirect bonding makes ideal setup and bonding a snap

Copenhagen, October 5, 2017 – 3Shape Orthodontics releases new indirect bonding solution, the future of bracket treatment, with exciting and innovative features to increase patient comfort and reduce treatment time.

“With (3Shape) indirect bonding, I can be much more precise and have better control of my bracket positioning and transfer those to the patient much more easily than before. It’s a more comfortable process for the patients and I need to do far less re-positioning of my brackets during the treatment,” says orthodontist, Dr. Lars Christensen, UK.

3Shape indirect bonding puts the orthodontist in control. You decide how much of the workflow to do inhouse and how much to send to your lab. 3Shape cloud-communications makes your file-sharing seamless.

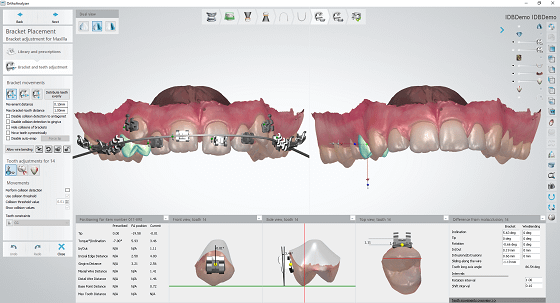

The bracket-placement workflow starts with a 3Shape TRIOS intraoral scan. The patient’s malocclusion is then brought up onscreen in the 3Shape indirect bonding workflow and with just a few clicks, an ideal setup is suggested.

On a split screen, one side shows the malocclusion with brackets, the other, the teeth in their final position. The professional can adjust the setup on either screen and the corresponding changes are made on the other screen; adjust the brackets on one screen and the teeth move on the other, likewise, adjust the teeth instead, and the brackets and wires move accordingly.

Professionals can choose from over 220 original manufacturer bracket libraries integrated within 3Shape orthodontics to design and work with, including: 3M, American Orthodontics, Dentaurum, Forestadent, Henry Schein Orthodontics, Ormco, RMO and more.

Once the ideal setup is approved an optional full prescription table is created by the software. Setup preferences can be saved for future cases as a template.

Professionals can then design and manufacture the transfer media using flexible design and production equipment. For example, trays made with soft biocompatible material can be printed on compatible 3D printers directly from the 3Shape indirect bonding workflow.

“3Shape strongly believes that indirect bonding is the future of bracket treatments. Our new and easy-to-use setup- based workflow makes it simpler for all orthodontic professionals to take advantage of indirect bonding and digital technology for precision bracket placement and improved patient care,” says Allan Hyldal, Vice President of 3Shape Orthodontics.

If you want to learn more about the 3Shape indirect bonding solution please visit: www.3shape.com/indirect-bonding

FDA market clearance for new and updated software features pending in the USA.

Contact your reseller regarding availability of 3Shape products in your region