So, your lab has been digital for a while. Are your solutions up to par? Globally renowned lab technician, Lee Culp examines the state of the union for dental labs and looks ahead to what are the skills and tools you need to know now, and in the future, to stay relevant.

I received an invitation earlier this year to lecture at the Academy of Prosthodontics. In preparation for the lecture, it encouraged me to reflect on my own lab’s past and my future in digital dentistry.

Looking back made me realize that my lab and I have been working almost exclusively digitally now for more than 22 years. In fact, our lab is considered to be one of the very first digital labs in the world.

For me to predict what might happen in the future, let us first look at the present and then consider what I believe labs will need to be ready for tomorrow.

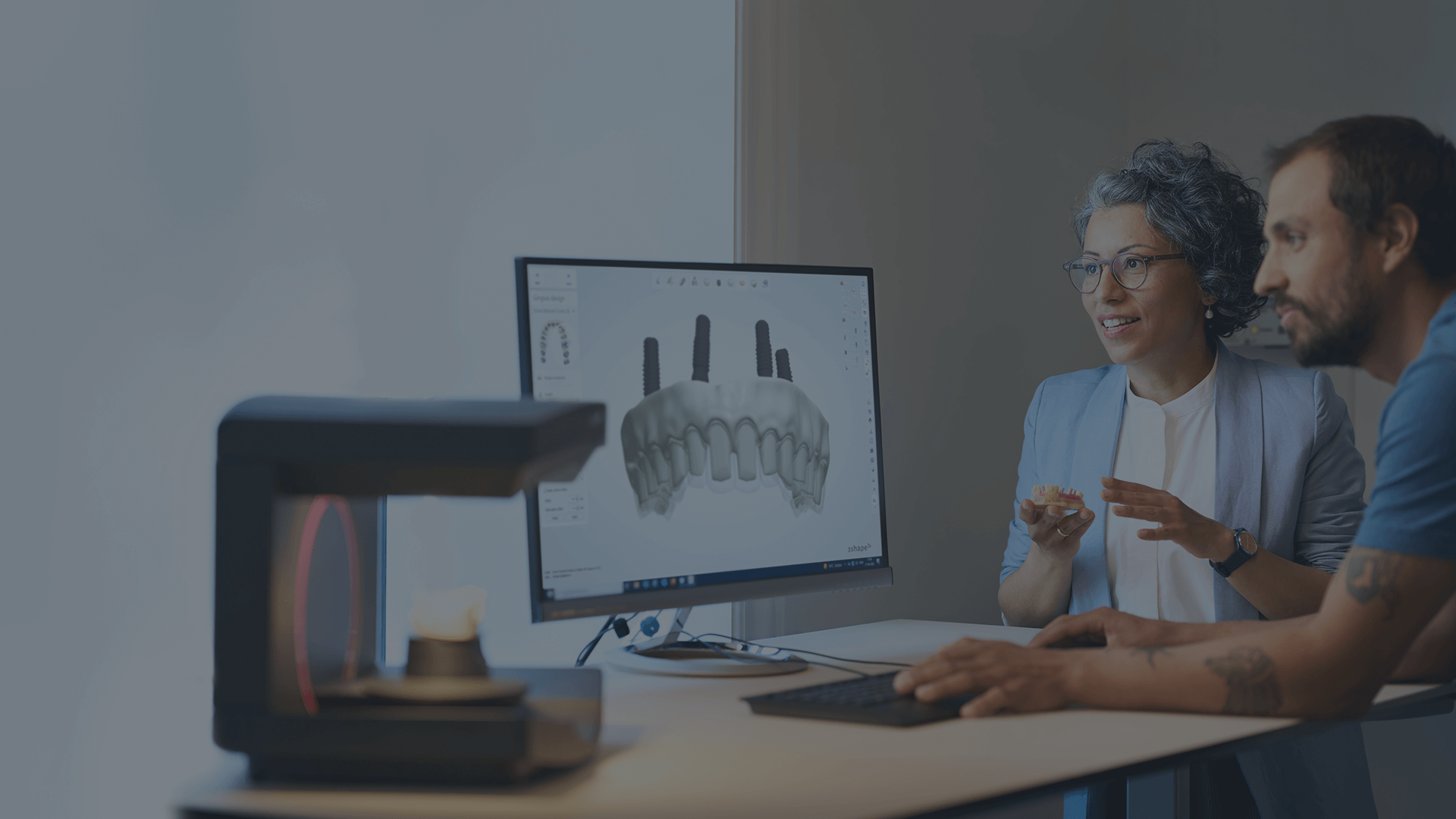

CAD-CAM software

Obviously over the last couple of decades CAD-CAM design software has changed dramatically.

The software has gotten so much better, and it allows us to do bigger cases more easily, and more complex work. I think that especially over the last five years, we have seen significant changes in software usability and capabilities.

Technicians have also gotten much more comfortable with, for example, designing indications like dentures. In fact, I believe that the software has gotten so good that future improvements will no longer solely be driven by software development but equally, by materials.

It will become much more about being able to process for example, dentures, both in milling and printing.

We will see big changes in the ongoing development and integration between software and materials.

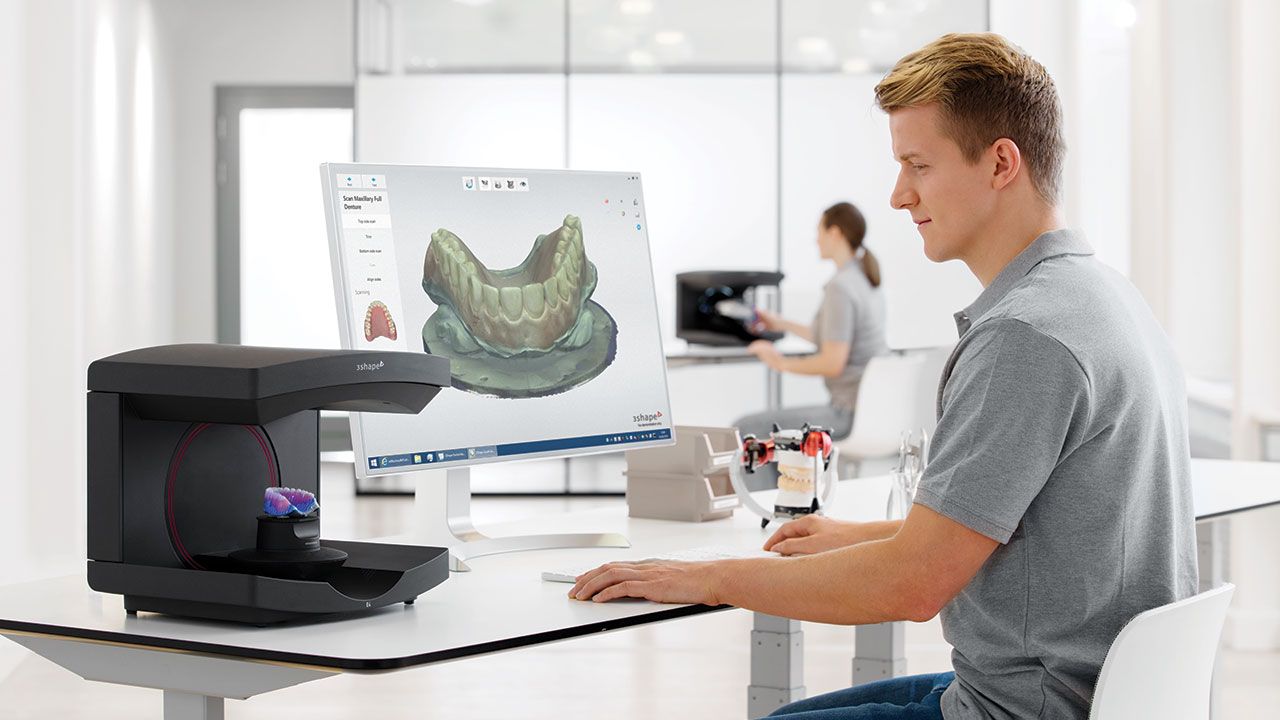

Will labs need new gear in the future? Lab scanners?

Another tremendous change I have seen over the years has been with lab scanners. The speed, the accuracy, they have made a big difference to our workflows.

Lab scanner speeds are simply amazing when compared to 20 years ago. We have a 3Shape E3 scanner and it is just so fast.

What is interesting is that with scanners like the E-series, they do not have a door. You just put the model in. I always wondered why there was a door on a scanner in the first place and just the fact of not having to open a door saves us time. For a lab, every second counts.

The time that we use to create a digital file or open a scanner door is labor lost. So, anything that is faster and not at a consequence of quality, is great. I am all for fast.

Why you need lab management software

On a related subject to lab efficiency and workflow speed are lab management software applications.

During the first half of my career, I was a small laboratory focusing on artistry like a lot of young technicians do today. Now, that's not a bad thing, so I'm not saying that in a negative way.

But I would encourage the younger technicians who are into the artistic part of being dental designer to remember you have a business.

One day you are going to wake up and think: I wonder how we make money?

When I first started out, I thought that I would never be part of a big lab. I would never do big production. I would never do this or that. But all the things I used to hate as a young artistic technician, we now do but at the same time, we do incredibly high-level work and can still match a single central.

Now to grow and especially manage your business, you need an LMS. With my LMS, I do everything from callbacks, retention, financial measurements, production measurements, case tracking and more. And I do it all from my phone.

It’s a necessity. And as a lab technician or owner, you need to get one because your lab is going to grow, trust me. Having every measurement, and like I said mine are on my phone, to have every financial production measurement and be able to check it any time and know what's going on, it is invaluable.

Protect your business with a service agreement

Lastly, and while we are talking about lab efficiency, you should also consider protecting your investments with a service agreement.

If you are a bigger lab, then you probably already have an agreement in place. But the smaller labs, the guys who do not think about, or think it's a waste of money or it's too much money, believe me, you need to back up your solutions with a service agreement.

It’s like LMS software, it’s just something you should have.

If you want to stay competitive, make sure that you are covered. You cannot afford to be down a few weeks because something is being repaired.

Making your lab more relevant now and in the future

As mentioned earlier, software will keep on improving but in the meantime, what we can do right now is change the way we apply it.

For example, learning to use the software for diagnostics instead of only designing can open a whole new door and revenue stream for your dental lab. I know because this is what happened to my lab.

We use 3Shape’s Implant Studio, Dental Designer, and the Ortho module. And instead of just making things with them, we also use them for diagnosis now.

As a lab tech, we are trained to push this button to make a crown, this button to build a bridge, and that one to make a denture. It’s powerful, but there is so much more you can do with your software.

With all these software modules and from a surgical perspective, ortho perspective or restorative perspective, we can do beautiful diagnostic work ups. And this is what has become a large part of my lab business now. Half of our work now is surgical. We are doing things that basically any other lab could be doing, but they first need to explore it.

We do not do ortho work at my lab, but we do use the ortho module to move teeth around and show people different results. We use Implant Studio for doing diagnostics for perio just as much as we use it for designing implants.

In short, and I believe in the future for labs to survive, they need to know that there is so many other ways that you can support your clients - other than just pushing the button to make a crown.

If you have a TRIOS digital impression and CT scan , you can do anything you can imagine with those two datasets and the software.

But, and most important, you first need to have the proper education. You have to have a solid foundation in ortho and perio, restorative, and surgical implants. So firstly, get a good education. And luckily, as a lab technician, that type of education is available to you.

Recently, we created a new digital group with Dr. John Cranham, who is the past clinical director at the Dawson Academy. And one of our goals is to show dentists how to use lab software to quickly look or create a patient diagnosis. In this way they can show their patient while the patient is still in the chair. Find out more about the group here: ccdigitaldental.com.

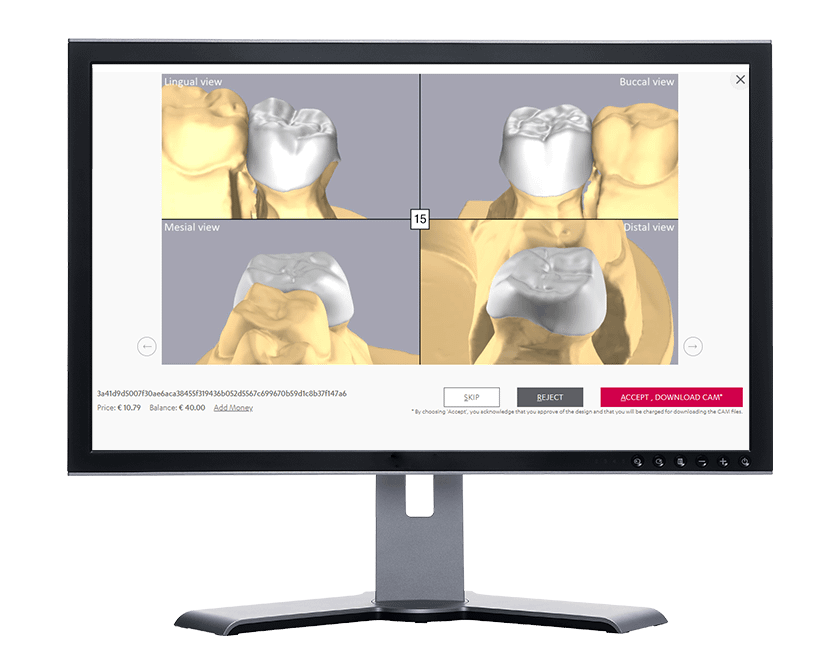

A new revenue stream for your dental lab

There is no reason for your lab not to provide this type of diagnostic insight.

In the former stone or analog world, this service or insight would take a couple of weeks to create. Now if the dentist has the laboratory software and/or a technician on hand, we can train them to position digital casts on a digital articulator, show their patient the functional aesthetic problems and propose a treatment very quickly. It no longer takes two weeks. The patient is still sitting in the chair.

But if you would like to successfully integrate this service into your lab, you need a few things. One, and most importantly, you need the knowledge. But secondly, you need to be able to market the fact that you can provide this type of service. It’s a challenge.

You need to be able to get the word out to your doctors that you provide this entirely new service.

So, in terms of you and your dental lab’s future, learn how to manipulate the software and then put the word out to your dentist clients that you provide diagnostic services.

Our laboratory has boomed in growth because of this.

We are able to offer our clients complete packages: the diagnostic part; the workout part, the surgical part, the restorative part, and of course, the final part.

We do everything, and the best part of it is, because we work digitally, we can show the customer and patient exactly what it's going to look like before we even start. It is just so powerful!

What will labs look like 5-10 years from now?

Now that we have everything in place, let’s talk about the future. Firstly, I see a lot more Artificial Intelligence (AI) coming in. It's funny. Everyone is talking about AI this and that, but 20 years ago we had auto-crown proposals.

The guys who are all excited about pushing a button and getting a crown are too young to remember the old software. That’s not to say that the solutions have not jumped by leaps and bounds in terms of predictability and accuracy over the years.

But we will still need technicians to finish. I've got a full-service digital laboratory, but I still need to have people at the end, cutting off things, centering things, glazing things, finishing things.

So, I think in the future, we may see less hands-on design, but a large part of our future will depend on, as mentioned earlier, developments in materials.

AI is going to do the heavy lifting in the future.

For now, as lab technicians, we need to always remember that we are a business. So, use an LMS, ensure your soft ware and hardware solutions with a service agreement, and learn to provide new services like diagnostics, to your clients. I know because it has worked for my lab.

From day one, twenty-two years ago, I always felt that people only thought of digital or CAD-CAM as a means to make things, and it is. But really, it is much more than that. Design and production are just one of the many components under the digital umbrella.